Featured Projects

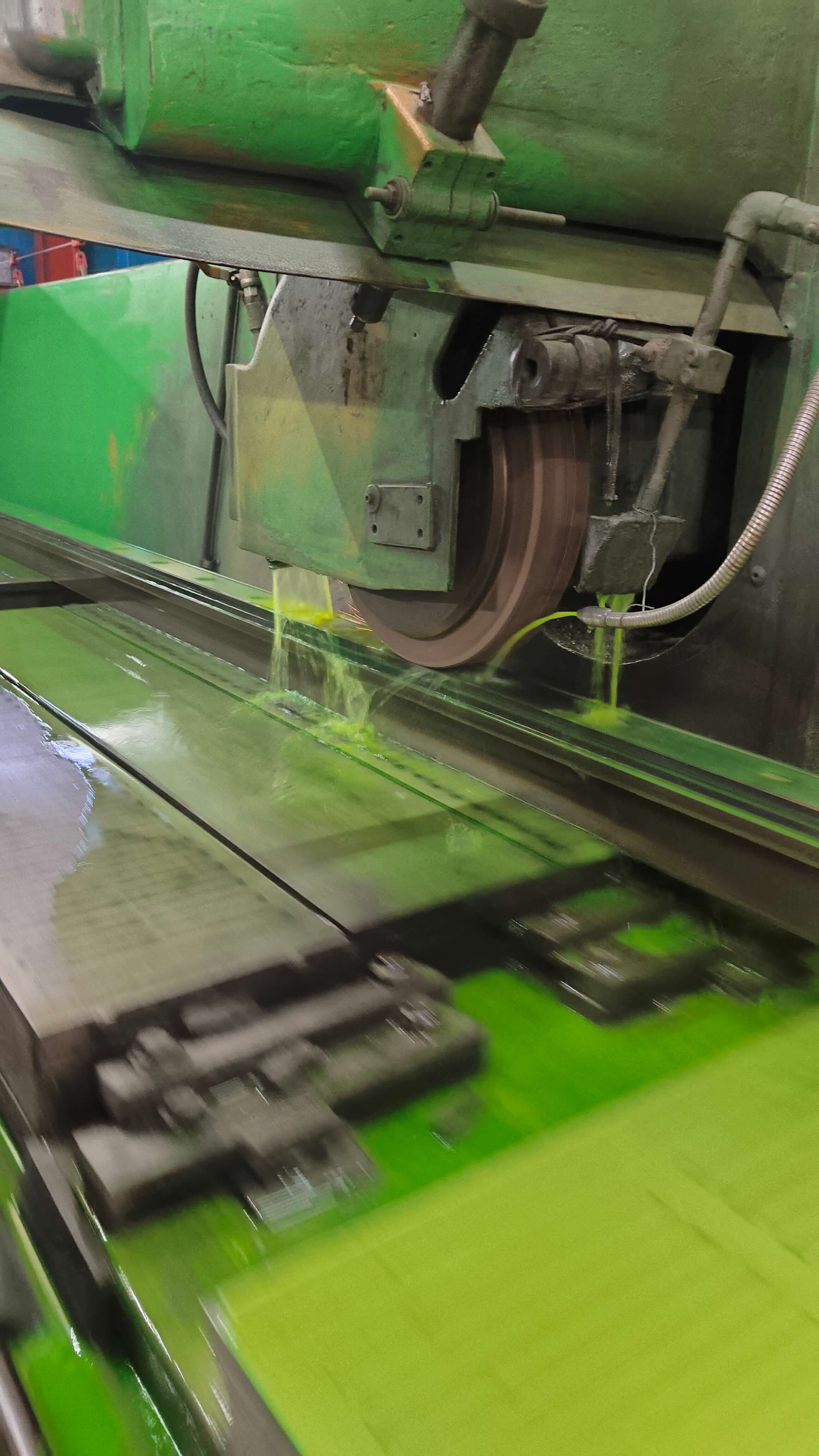

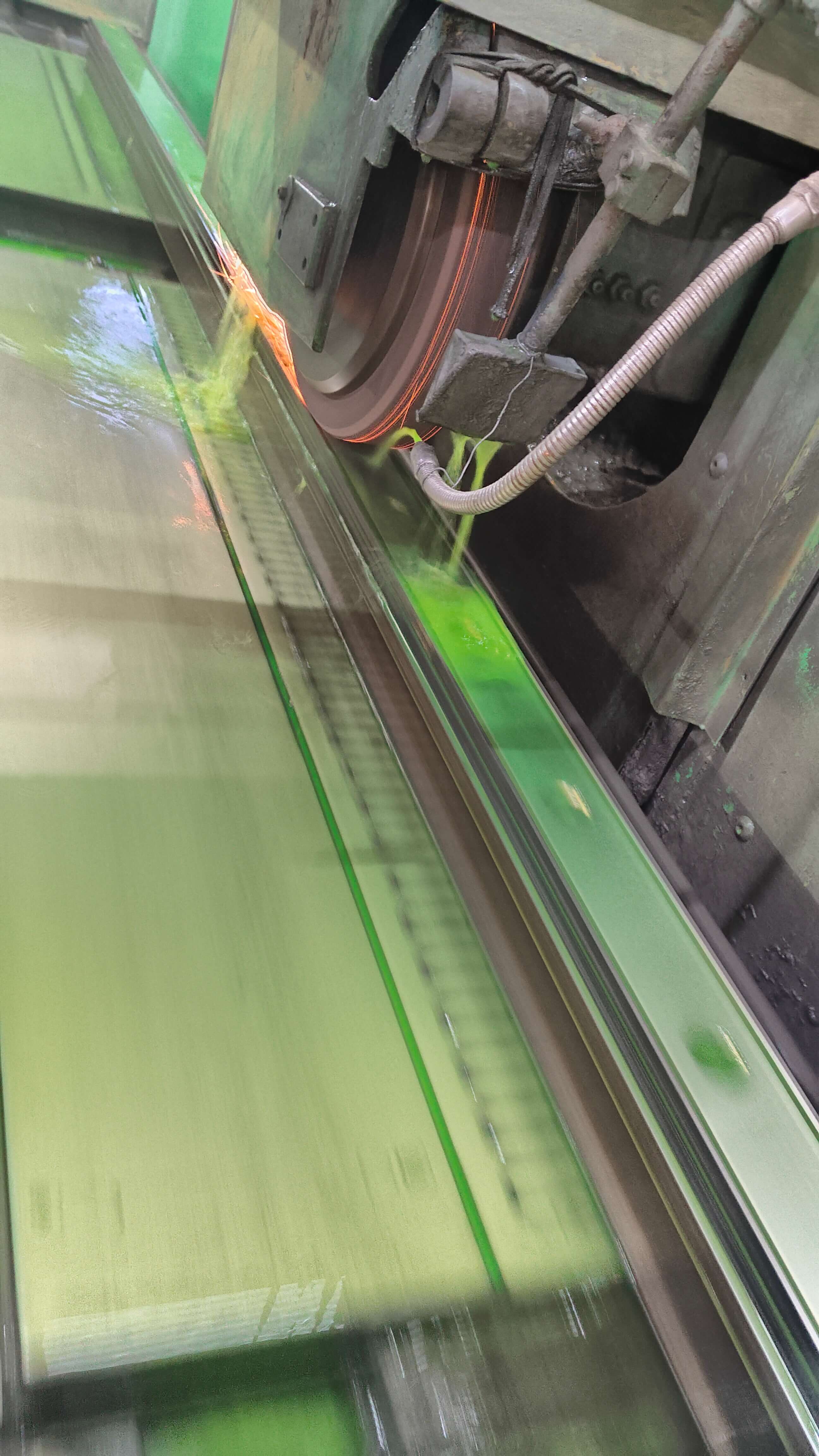

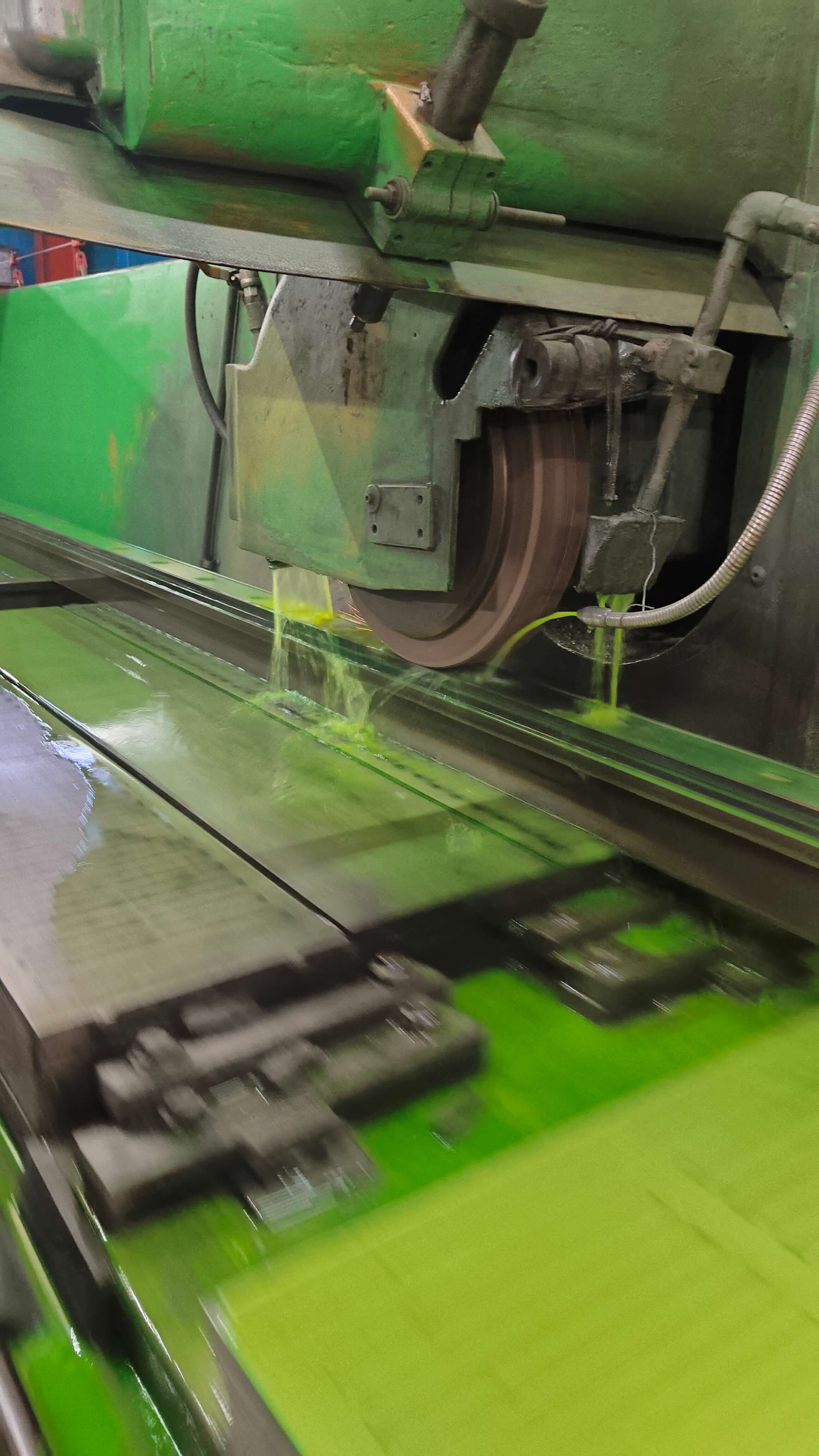

Project 1: Fischer Cutter Blade Grinding

Sri Devi Engineers provided precision grinding services for Fischer Cutter Blades, used in radial tyre sheet cutting, to clients including J.K. Tyres and Apollo Tyres. Our expertise ensured high-quality results that met our clients’ stringent standards.

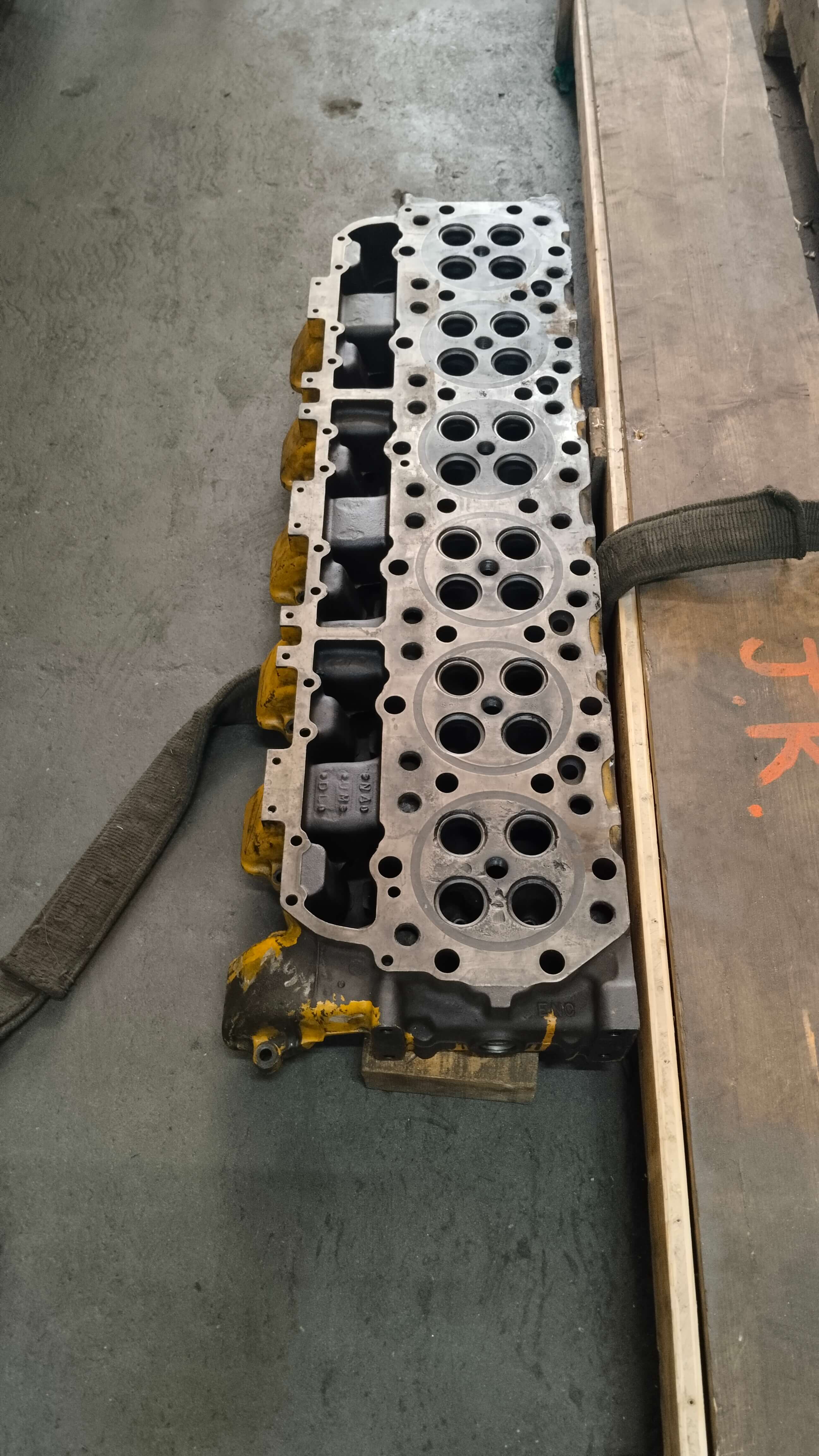

Project 2: Industrial Equipment Grinding

We partnered with L&T and Godrej to provide specialized grinding for industrial equipment components. Our team leveraged advanced technology to deliver consistent, accurate results within tight project timelines.

Project 3: Customized Knife Grinding

For clients like Ceat Tyres, ATC Tyre Ltd.(Yokohama) and Continental India Ltd., Sri Devi Engineers provided customized grinding solutions for Konsta knives, optimizing them for use in tyre manufacturing processes. Our services have enhanced their operational efficiency.

Project 4: Aluminum Grinding for Industrial Use

Our team at Sri Devi Engineers has also specialized in aluminum grinding, working with packaging industry to meet precise specifications needed for industrial applications. Our advanced grinding process ensures durability and a perfect finish, enhancing material performance.

Case Studies

Case Study 1: Precision Grinding for Aerospace Components

We faced unique challenges in meeting aerospace-level precision for an L&T project. With customized processes and precise machinery calibration, our team delivered results that adhered to strict quality standards.

Case Study 2: High-Tolerance Grinding for Energy Sector

Our expertise was leveraged in a project for Crompton Greaves and Jet Airways where we provided high-tolerance grinding for energy sector components. The project was completed on schedule, meeting all quality benchmarks.

Image Gallery